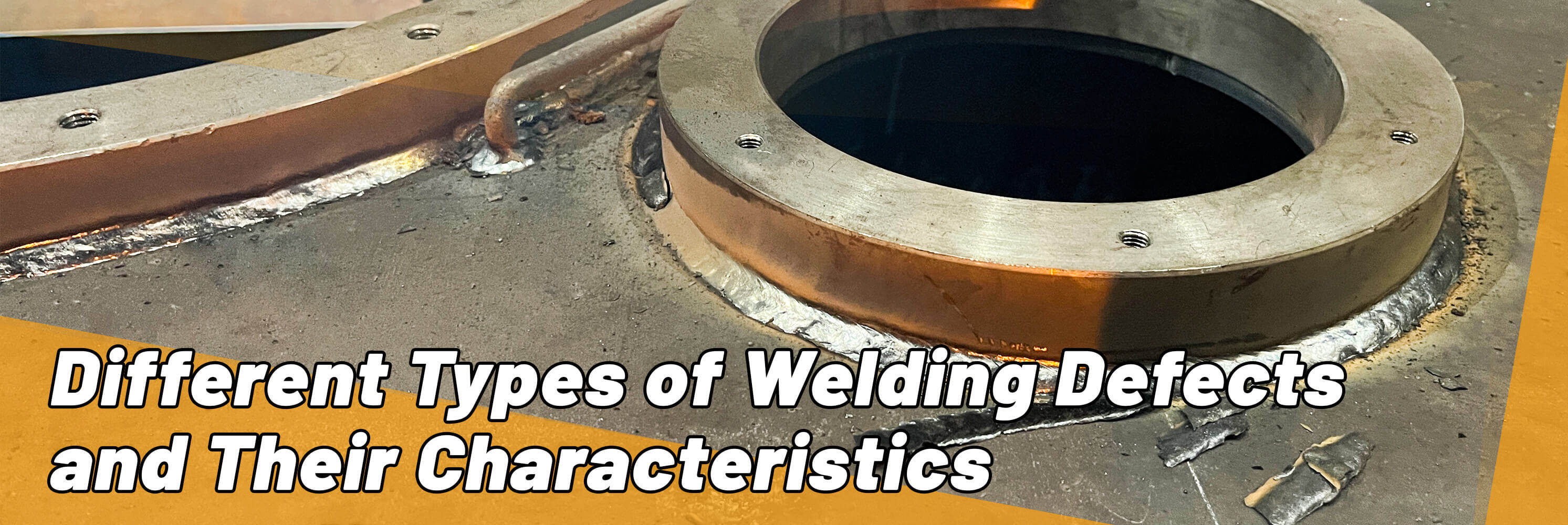

Understanding the Different Types of Welding Defects and Their Characteristics

Welding defects are problems or mistakes in a weld that do not follow the rules set by groups like AWS, ASME, or ISO. There are various types of welding defects, including porosity, lack of fusion, and cracking. These defects often occur due to poor welding techniques or improper joint preparation. Welding defects weaken the weld and reduce its strength, which can also shorten the lifespan of the weld. Understanding the different types of welding defects helps workers maintain high-quality welds, prevent premature failure, and ensure the safety of structures and equipment.